Because is strong, lightweight and corrosion resistant!

Lets dive into all the properties (positive and negative) of the carbon fibers and discover why do we want to use them as a building material in the different applications.

But first lets look at what carbon fibers are!

Carbon fibers are carbon atoms combined together in a crystalline structure that forms a strand that can be thinner than a human hair. Several thousands of fibers are bundled together to form a tow, which can be used by its own or woven together into a fabric. This is where the fabric names 3K, 6K, 12K etc. come from. 3K meaning that there are 3000 strands in a tow of a fabric. Carbon fibers are usually combined with plastic polymer resins to form a completely new material by its properties carbon fiber composite.

Did you know that Sir Joseph Wilson Swan first created carbon fiber in 1860 to use in an early incandescent light bulb? And that in 1879, Thomas Edison used cellulose-based carbon fiber filaments in some of the first light bulbs to be heated by electricity? If you want to know more about a brief history how carbon fiber was developed check DragonPlate’s history post.

CARBON FIBRE COMPOSITES ARE 5-TIMES STRONGER THAN STEEL AND 2-TIMES AS STIFF

Carbon fibers in form of carbon fiber composites with epoxy or polyester resins are incredibly stiff and strong. With other words, we can achieve same rigidity of the steel material with 5-time less weight.

Is CARBON FIBER COMPOSITE a relatively different material?

Yes! The structural properties of carbon fiber composite are determined completely with the direction of the fiber reinforcements, which can be controlled during the production process. In this way the performance of the part can be controlled achieving best strength and stiffness properties where needed. In addition the resin (polyester or higher performance epoxy resin) properties can also be controlled, contributing strength, durability and chemical resistance to the carbon fiber composite.

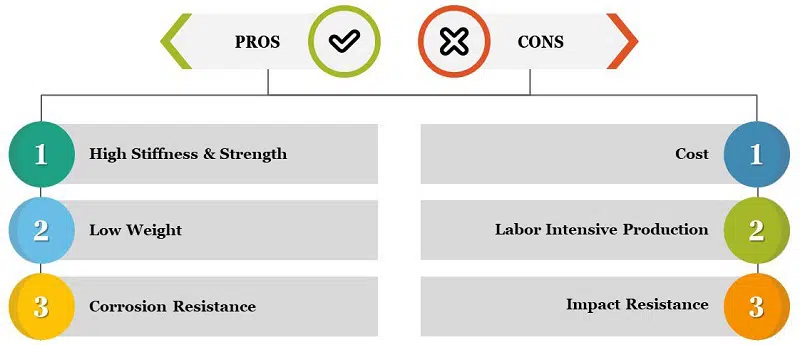

What are the 3 PROS and CONS of carbon fiber composites?

Carbon fibers have high stiffness and high tensile strength. They have low weight/strength ratio and they are corrosion resistant. On the down side the material itself is relatively expensive and production of carbon fibre composites can be labor intensive. If carbon fibre composites are exposed to impact load they can also be brittle.

What are some OTHER positive mechanical properties of the carbon fibre composites?

Carbon fiber composites are very good at vibrational dumping, they have low coefficient of thermal expansion, high chemical resistance, resistance to extreme heat and resistance to fatigue. All of these positive characteristics have propelled the carbon fiber composites into wide use in industrial sectors.

Will carbon fiber composites in the future replace steel and aluminium?

Carbon fiber composites are emerging as strong alternative to steel and aluminium in aerospace, automotive, sports, infrastructure, marine & military sectors. Some studies projects 5 – 10 % market share growth of carbon fiber composites in the future. The production is still costly and labor intensive, but high strength and low weight of the carbon fiber composites are the winning properties that propels the material to the very peak of the industry high performance materials.

Have we answered the question why use a carbon fiber composite for producing different products? Comment below why would you use a carbon fiber for production of a product?